The Importance of Railroad Track Monitoring

Track Monitoring is the measurement and reporting of ground and track elevations at a railroad utility crossing.

Track Deflection refers to movement or interference of the railroad track due to construction activities.

Whenever a public utility such as a gas pipeline intersects a railroad right-of-way, a railroad crossing permit is required. However, when factors such as geometry, site constraints, or geological conditions dictate that a utility must be installed shallowly below the rail track, this permitting process becomes more complex. When it comes to shallow railroad utility crossings, meticulous railroad track monitoring is essential to avoid track deflection and achieve successful permitting.

When a utility must be installed within a track’s “risk zone” which may cause track deflection, additional survey track monitoring is required as part of the permitting process. This allows the team to monitor the rail infrastructure in real time, and alerts to possible construction shut-downs.

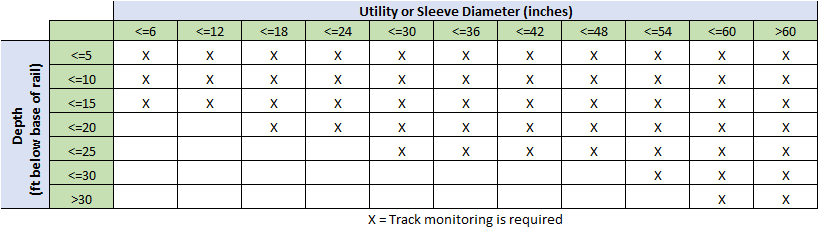

The following table summarizes when track monitoring is typically performed:

Key Steps for Successful Shallow Railroad Utility Crossings

Key #1) A Detailed Track Monitoring Plan

Before construction can begin, a work plan is approved describing specific project details (such as site layout, schedule, means and methods, and general requirements) to ensure railroad compliance. Much of this information can be provided by the horizontal directional drilling (HDD) contractor. However, one component must be prepared by a surveyor--the track monitoring plan. The track monitoring plan specifies what part of the railway will be monitored, how it will be monitored, frequency of monitoring, and threshold deflection values to be reported to the construction observer (a railroad employee or 3rd party observer).

Typically railroads will require deflections to be measured to ⅛ inch. The surveyor must propose survey equipment and targets that meet this level of accuracy. Once complete, the track monitoring plan is combined with the work plan and submitted to the railroad for approval.

Key #2) Team Coordination Before Commencement of Work

Coordination is essential among the HDD contractor, surveyor, and railroad field personnel. Once the work plan is approved, railroad field representatives are contacted at least 10 days prior to any work within the railroad right-of-way. The railroad will then determine any necessary safety measures, such as flagging. Whether or not safety measures are required, work cannot commence until the railroad provides written authorization, so the contractor needs to stay informed.

Once authorization is given, the surveyor will need adequate notice to set up track monitoring and take baseline track and ground elevation measurements before the contractor commences work.

As the utility provider, it’s important to verify that the contractor has prepared contingency plans that provide means and methods to prevent track deflection, and be ready to implement with required materials, equipment, and personnel.

Key #3) Field Implementation and Railroad Approval

During construction the railroad representative will be on site while the surveyor actively monitors the track and ground elevations in accordance with the monitoring plan. Deflections greater than ⅛ inch are reported to the railroad representative and the contractor. The contractor then determines the appropriate contingency plan(s) and immediately seeks approval from the railroad representative. Work must immediately stop if there are deflections greater than the value set by the railroad through the crossing permit.

To maintain railroad compliance, daily track measurement reports are required by the railroad representative. Track monitoring must continue for 7 days upon completion of construction to confirm that rail infrastructure was not impacted. Reporting to the railroad should be concise and easy for the railroad to conclude that deflection limits were not exceeded.

Railroad crossings can be challenging, especially shallow crossings. However with a thoughtfully prepared track monitoring plan, coordination with construction entities, careful implementation, and concise reporting, a successful pipeline installation can be achieved.

Railroad crossings can be challenging, especially shallow crossings. However with a thoughtfully prepared track monitoring plan, coordination with construction entities, careful implementation, and concise reporting, a successful pipeline installation can be achieved.

If you have any questions about this process, please contact our lead Surveyor, Cory Dopp.

References

GUIDELINES FOR ABANDONMENT AND REMOVAL of SUBSURFACE UTILITY STRUCTURES, UNION PACIFIC RAILROAD COMPANY, May 2018.

PIPELINE CROSSING AGREEMENT, UNION PACIFIC RAILROAD COMPANY, Nov. 2019.